A more than complex challenge

The technological demands of precision motion and robotic utility have never been greater. Surgical robotic technologies require ultimate precision and high force torque sensitivity, while automated logistics robots and emerging humanoid technologies require an equal balance of freedom of movement with accuracy and extreme safety. In next-generation factories, industrial robots are used to perform an ever-increasing array of advanced production and assembly tasks with increasing precision, and multi-functional utility.

Over a third of Novanta’s business is dedicated to the development of products and technology that support these disruptive applications, through an unwavering commitment to pushing the boundaries of physics with our advanced product solutions and NPI roadmaps. Novanta powers these industries through its unwavering dedication to developing world-class motion control products and embedded technologies that deliver the required levels of precision, safety, speed, performance, and energy efficiency to these applications.

Motion Control Technologies

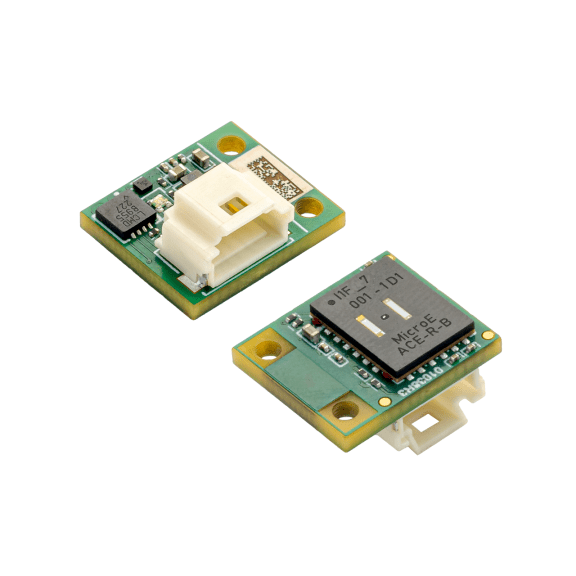

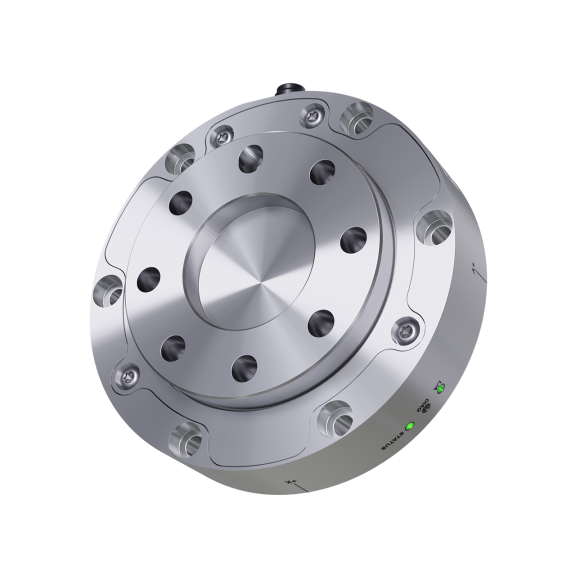

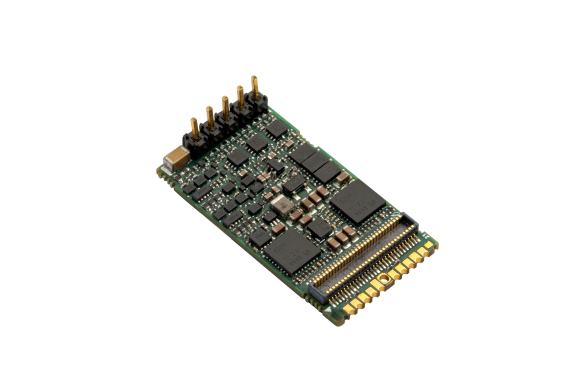

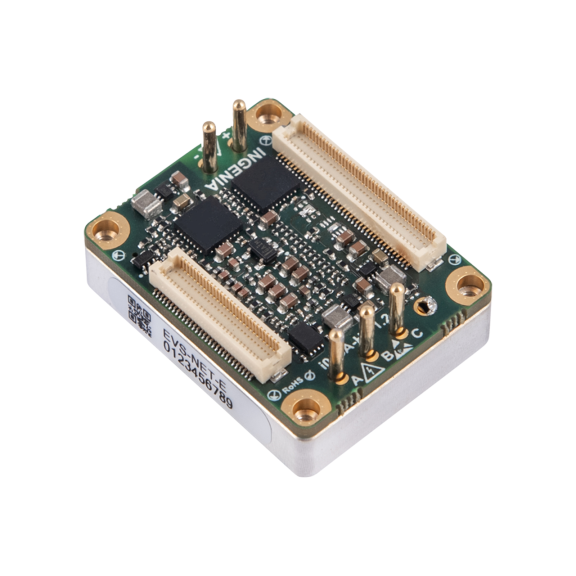

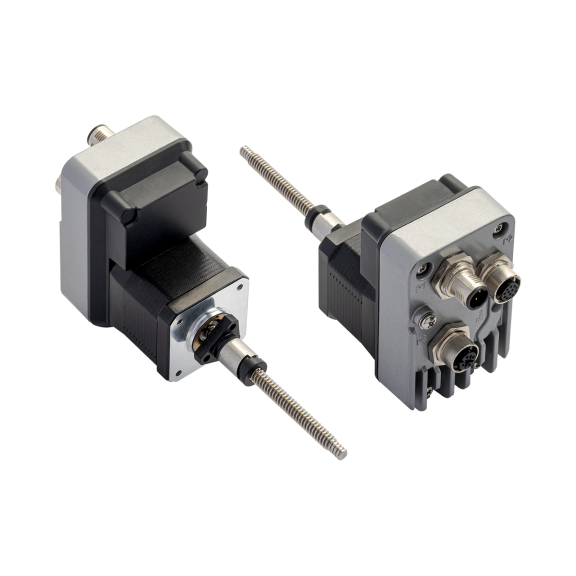

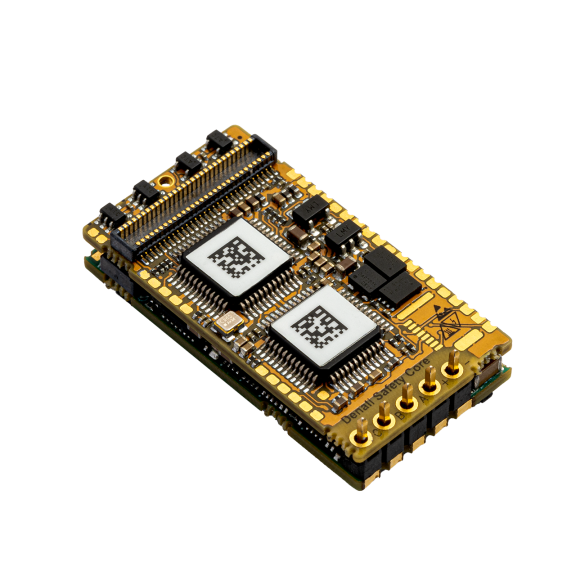

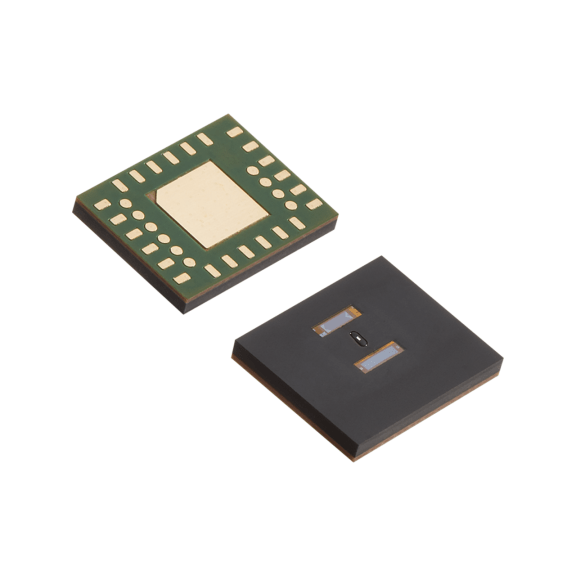

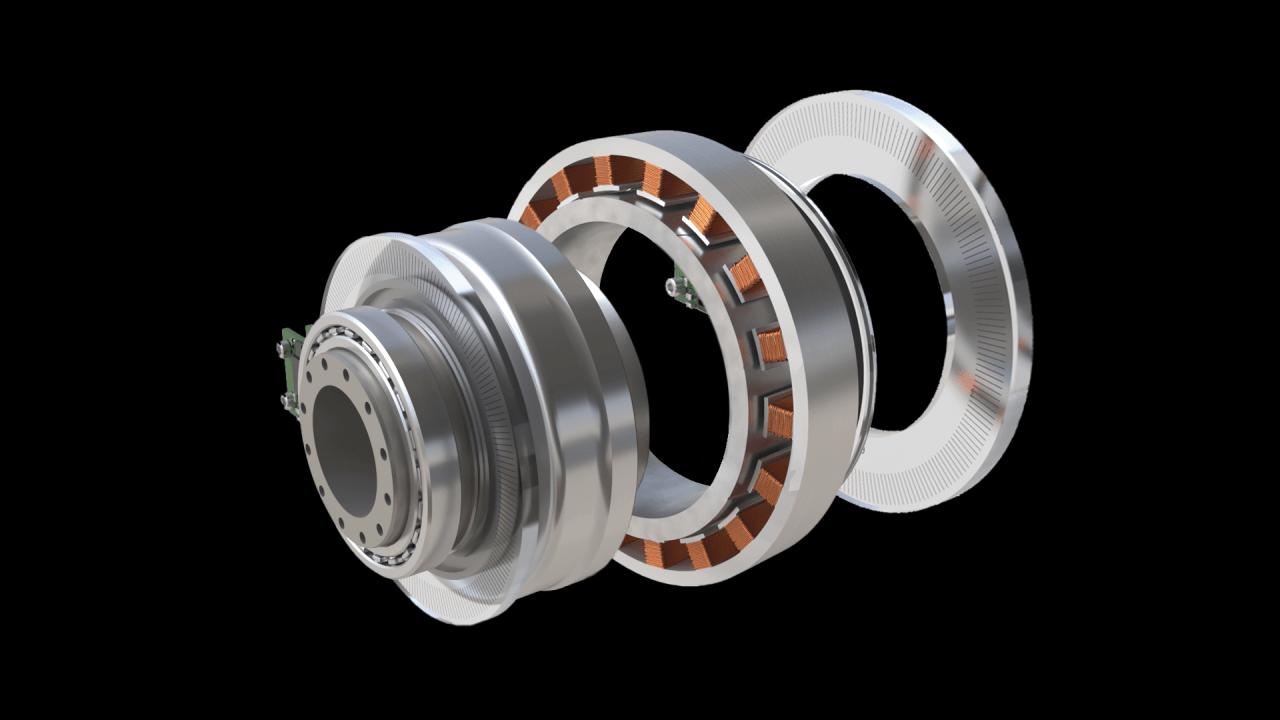

The Motion Stack is the answer to today’s motion control challenges. Design engineers must piece together, in a compact way, a complex puzzle of motion control components consisting of motors, encoders, drives, torque sensors.

The real challenge lies in seamlessly integrating these technologies together and making them work smoothly to achieve their motion goals. Novanta simplifies this journey for its customers by holding a unique position in the market through offering the entire product ‘stack’ – from servo controller, to sensor, to motion.

Read more about our range of fully integrated motion technologies here.

Robotic Automation Solutions

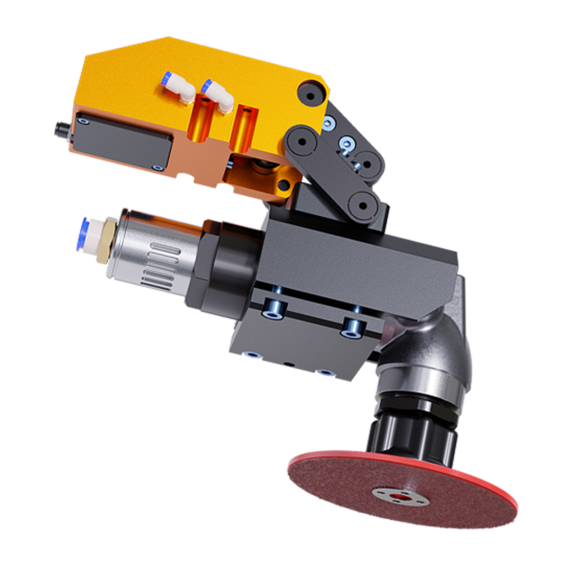

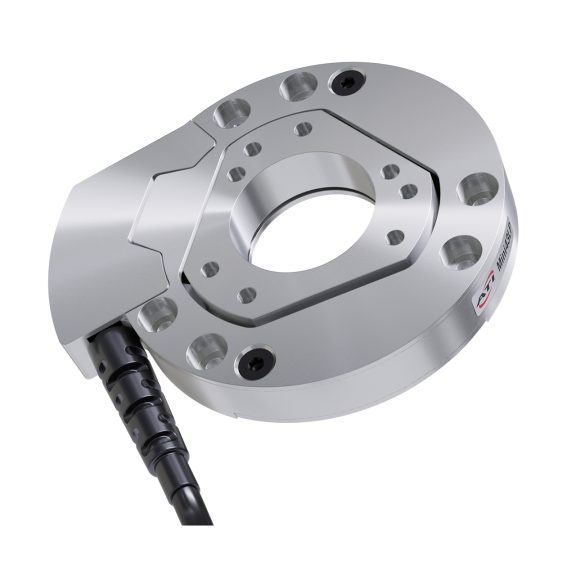

While robot arms and industrial automation systems represent cutting-edge technology, their specific task functionality and overall utility relies on the use of ‘end-effector’ technology — interchangeable function modules that bring limitless functionality to the robot.

Novanta is a market leader in this industry with a comprehensive series of ‘end effector’ product families dedicated to the automation of factories through the expansion of robot utility.

In this section, you can find out more about our ranges of ATI Automatic Tool Changers, Multi-Axis Force/Torque Sensing Systems, Utility Couplers, Material Removal Tools, Robotic Collision Sensors and much more!

InMotion Magazine

Read our very own Robotics & Automation magazine!

Discover news, products, and company insights.