Battery Manufacture

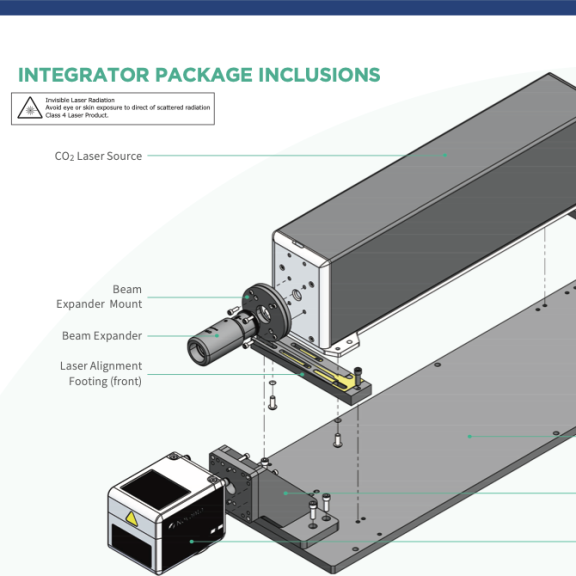

In the process of manufacturing batteries, tasks involving electrodes, cells, and EV battery packs are executed with great accuracy and consistency using laser systems. These digitally controlled lasers do not physically touch the material during any stage of the process, allowing for the careful handling of delicate materials and preventing harm to unprocessed areas. Novanta excels in this area by providing a wide variety of products to this application area, including laser sources, beam steering, and tailor-made scanning heads These can be supplied as separate components or as part of integrated sub-systems, together with our robotic tool changing technologies which are widely used in this area.

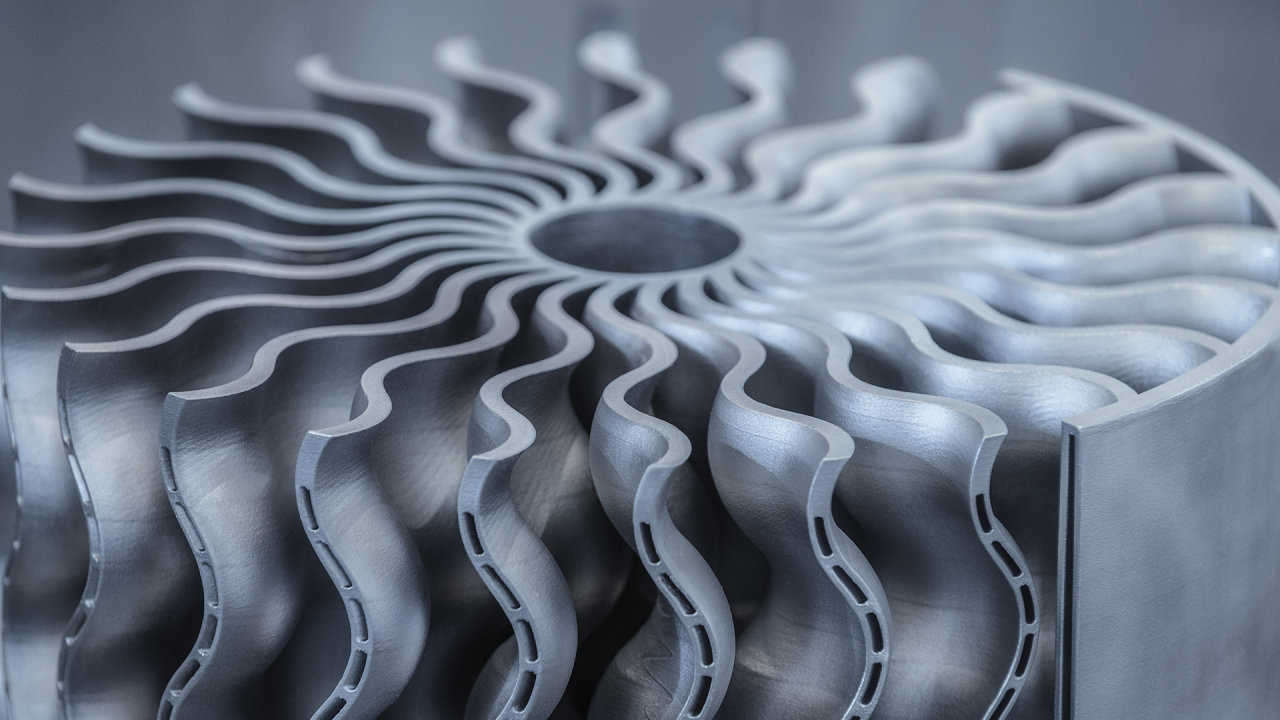

Additive Manufacture

Laser additive manufacturing is a revolutionary production technique that uses lasers to construct three-dimensional objects layer by layer. This process involves the use of a laser beam to melt and solidify material in a powder bed, based on slices of a corresponding three-dimensional computer-aided design (3D-CAD) model. It offers unprecedented precision, efficiencies, and possibilities in the manufacturing industry, enabling new approaches in product design and is transforming the landscape of production. Read here about how Novanta’s lasers and beam steering technologies are powering this groundbreaking industry.

Humanoid Technology

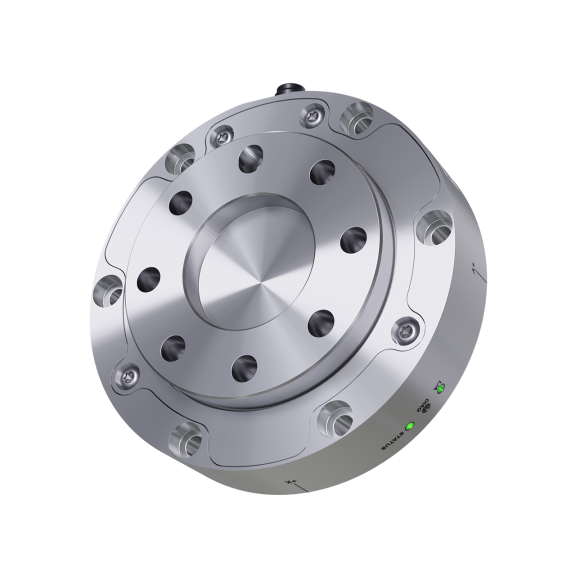

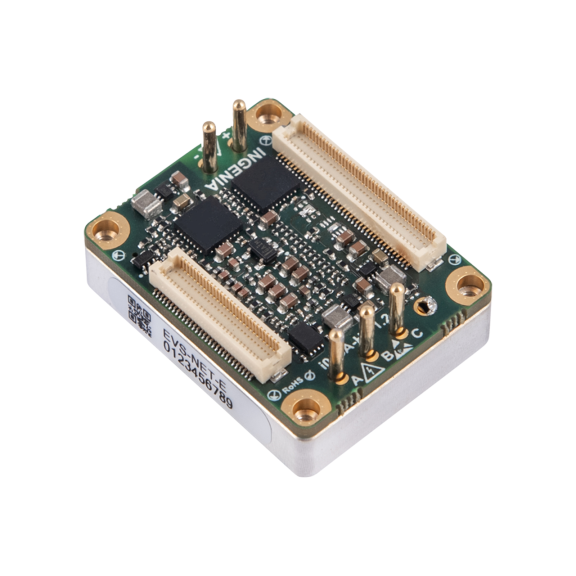

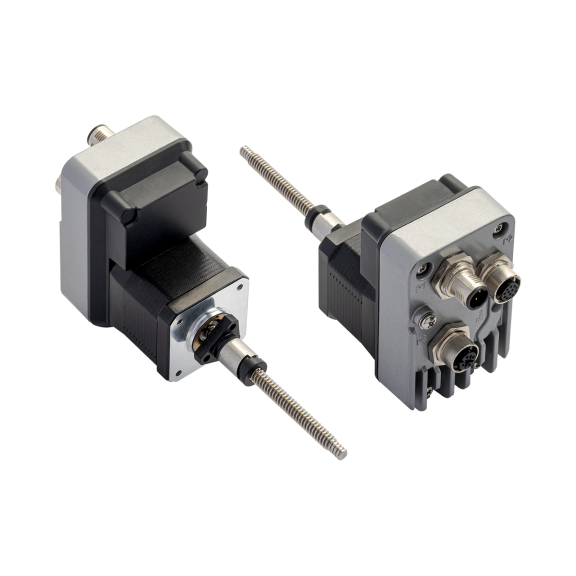

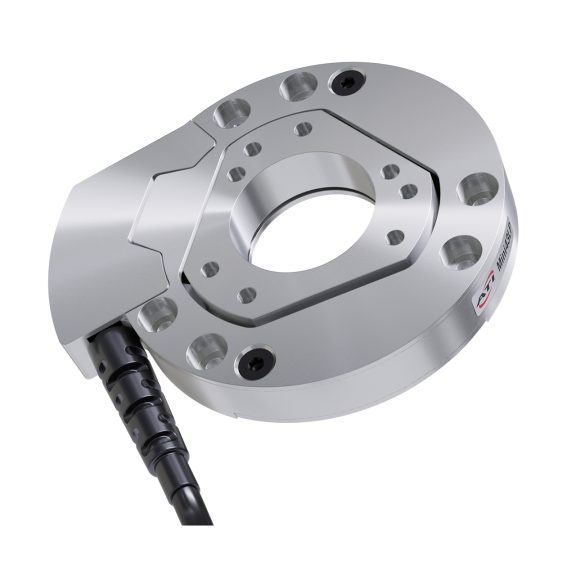

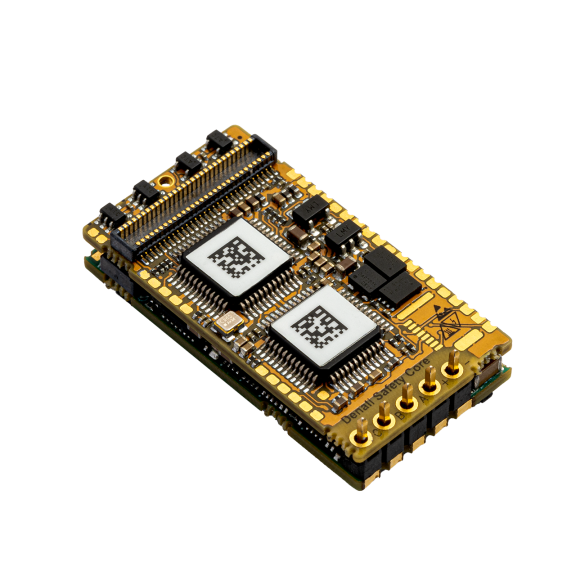

The production stage of Humanoids is anticipated within the next ten years, with safety standards already well defined. Looking further ahead we could see humanoids entering homes to assist with routine tasks in the following 15-20 years.

Pioneering companies are faced with complex hardware challenges, including developing more advanced actuators for precise movement and creating more robust and power-efficient systems. Read more about how Novanta provides todays humanoid developers and factories with advanced motion and force torque technologies that helps solve these complex challenges.

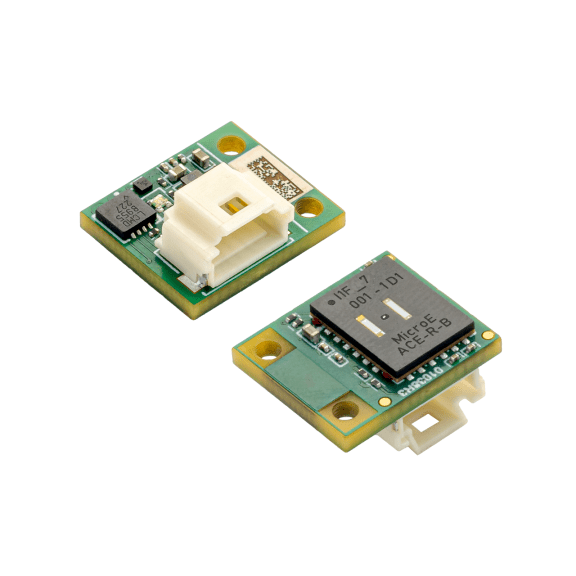

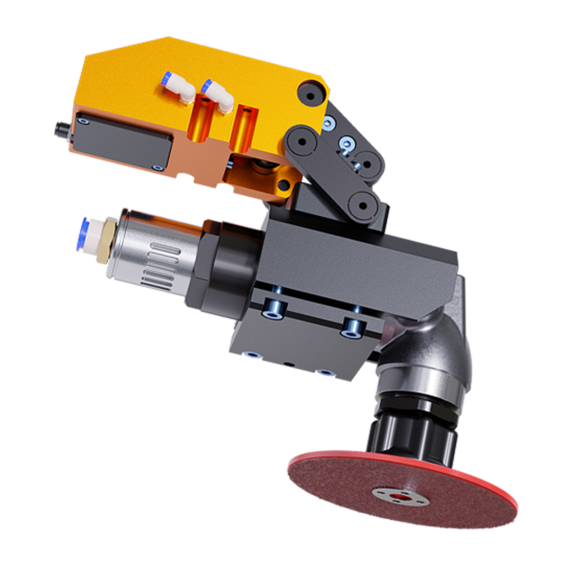

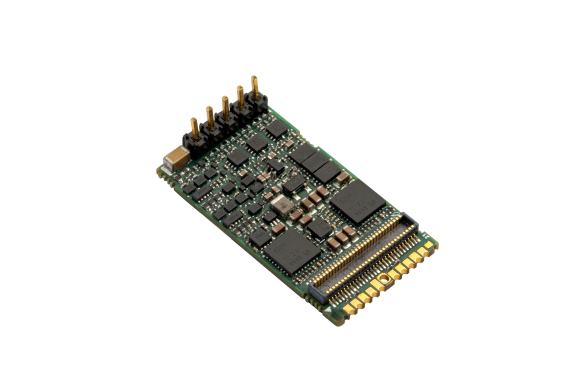

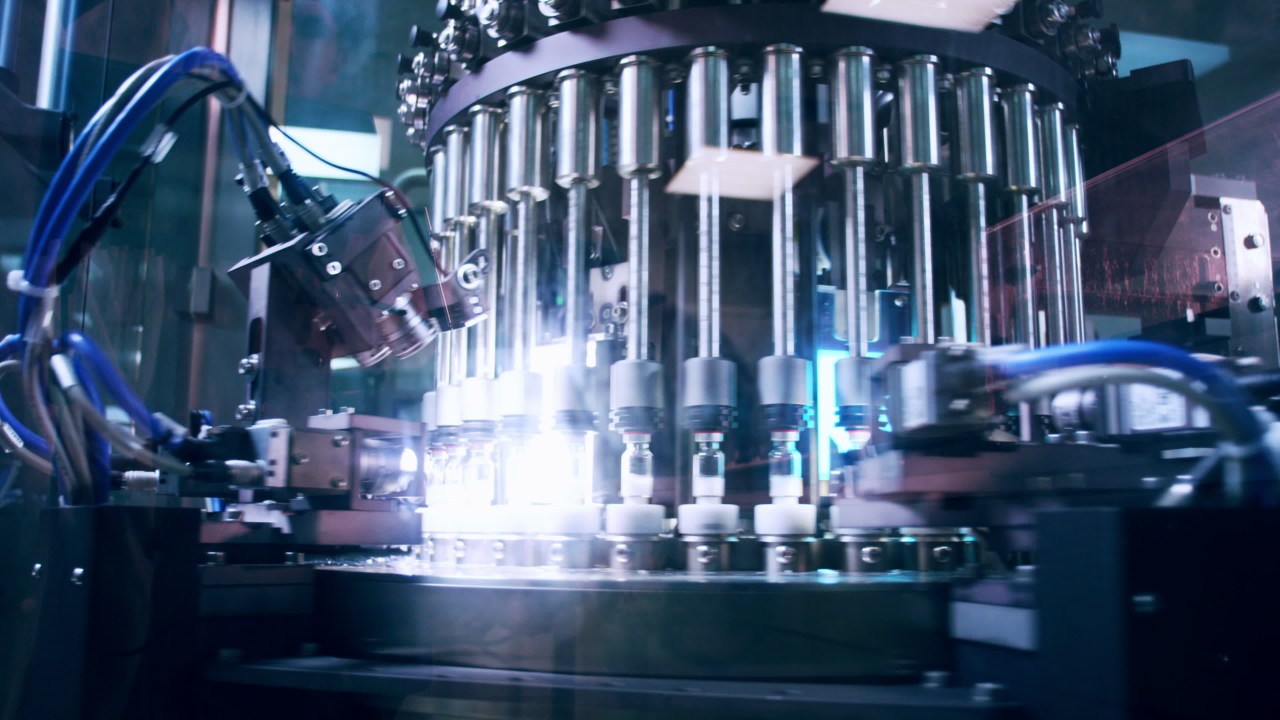

Industry 4.0

Programmable laser and robotic technologies are driving a revolution in factory automation. From product manufacture, to robotic logistics to automated packaging, the convergence of IT with factory operations and programmable, multi utility robotic production technologies is enabling lower costs, increased flexibility and mass customization of products. Novanta technology is embedded deeply into many of these application areas – from our RFID modules and precision motors in logistics robots, across to the latest laser perforation technologies in packaging and converting industries.

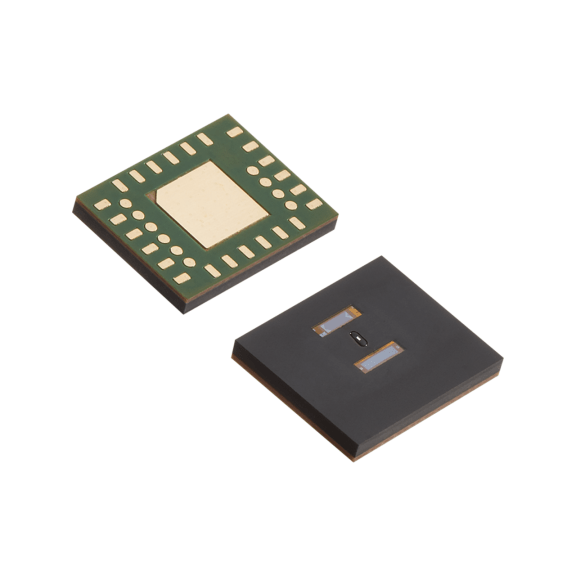

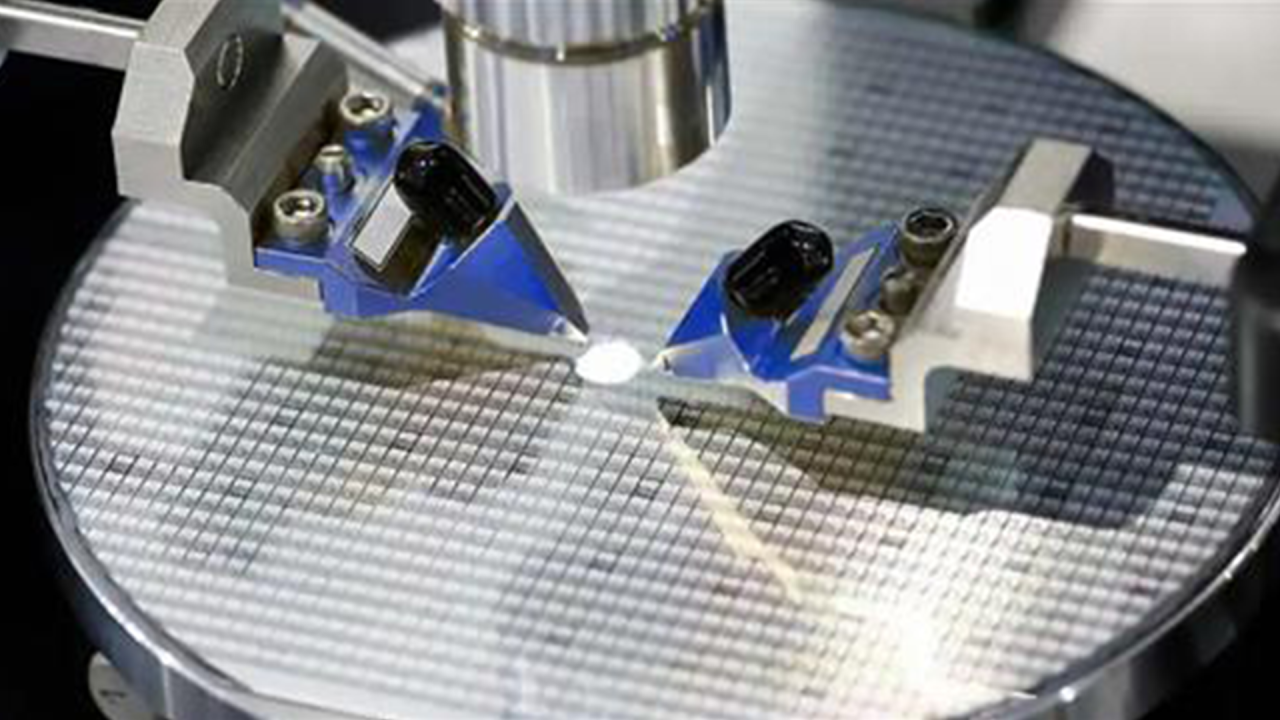

Semiconductor

As the world continues to demand increasingly advanced semiconductors to power everything from appliances and airliners to autonomous cars and artificial intelligence, so the demand increases on manufacturers to improve efficiencies and throughput of the production of semiconductor components.

You’ll find Novanta technologies powering many of the next generation of semiconductor manufacturing processes – from ultra high performance metrology lasers and beam scanning solutions across to our XYZ positioning mechanisms and high speed motor technologies.

Solar

The solar photovoltaic market is experiencing robust growth, being driven strongly by renewable green energy targets and new building regulations. Large-scale solar farms are being developed to meet energy demands and renewable targets, while ongoing R&D is leading to more efficient solar panels and advances in battery technology. Novanta brings a series of manufacturing technologies to this market, including the latest laser scribing technologies that are helping to unlock efficiency gains in this important and rapidly expanding sector.

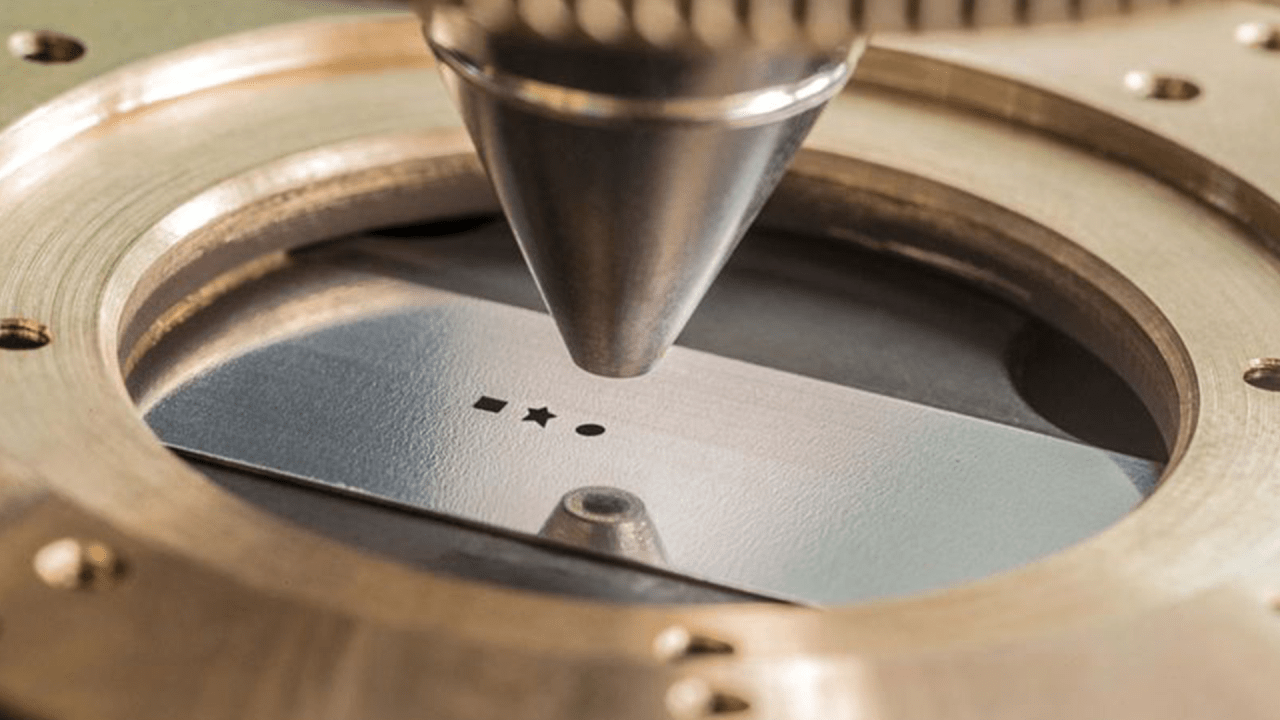

Micromachining

Micromachining is a precision manufacturing process that involves creating extremely small parts and complex features at the micron scale, often using lasers, high speed positioning technologies. This application is driven by the need for miniaturization of components, across a wide spectrum of industries including healthcare, electronics, aerospace and e-mobility. Novanta holds deep proprietary expertise in a series of manufacturing technologies that underpin this application, including our proprietary zero taper micro laser drilling systems, and our ultra high speed air bearing motor drilling technologies.